Project Manta Rays| Trash Cleanup

Project Details

The Challenge | Trash Cleanup

Project Manta Rays, Cleaning Earth's Oceans one particle at a time

The project is about filtering microplastics from Earth Oceans throuigh biomimickry of the filter feeding process of aquatic animals, utilizing the hydrodynamics of manta ray bodies in manta ray-like autonomous cleaning robots that would filter out micropl

Challenges: The project would have done a better job if we had more time, the 3D model printing took the entire 24 hours of the Hackathon then failed. A member of the team left due to family emergency and didn't come back. Die to shortage of time, there was no time left to even procure the necessary sensors, equipment. The team was self-sufficient as the engineers on the team had leftover Arduino boards, GPS and RF modules and we had to make do with paper at the last second as the 3D printing failed spectacularly.

Project Manta Rays Team Proposal

Introduction & Idea Validation

According to NASA Earth Data (powered by EOSDIS), “Unwelcome enrichment in the Arctic” by Michon Scott as part of the “Sending Our Planet” publication of 2018, Microplastics in the ocean are a big problem that is far more pressing than larger debris that could be collected via initiatives like “The Ocean Cleanup 001, founded by Boyant Slat” as microplastics are much harder to harvest and infiltrate, via wave movement, the most pristine of environments like the Arctic and soon could potentially reach the shores of Antaractica, even being found within the smallest of Arctic crustaceans that is considered vital for the food chain in that ecosystem. The project idea applies principles of mimicking filter-feeding processes applied by microplastics. NASA published an article on one of its publications that could be checked out via this link (about finding microplastics all the way up to the Arctic): https://earthdata.nasa.gov/learn/sensing-our-planet/unwelcome-enrichment-in-the-arctic

Moe on the filter-feeding biomimickry: https://www.sciencefriday.com/educational-resources/engineer-a-filter-feeder/

Link to the project’s video: https://www.youtube.com/watch?v=h2n4UyrdOic&rel=0

Problem definition:

The problem that the submitted solution is trying to solve is the proliferation of microplastics that is floating on the surface of the ocean in garbage patches. The submitted solution is geared towards harvesting those microplastics from the surface of such patches in the open water of the ocean.

Solution:

The solution is a combined system that includes:

- Central Station: A repurposed oil tanker, or freighter. The ship would have microplastic compressor in pellets for eventual transfer and recycling at mainland facility. The central station would have communication system for receiving and transmitting and satellite internet receiving antennas and systems:

- Swarm robotics of manta ray-shaped robots. The robots would have two main functionalities: gathering data from the surrounding environment and sending them to the central station and receiving commands from it and filtering out micro plastics.

- Offsite cloud based command system: That system could be one managed at NASA facilities where AI algorithms use satellite GIS data, in real-time coming from satellite systems and from the manta ray robots via the central station relaying interlink and then sending real time commands to the robots via the central station communication protocol via Radio Frequency. For the sake of the competition and the Hackathon, we would assume that such system already exists and the manta ray robots would send it data and would receive from it commands.

Each robot would have the following items:

- Body: The body would be composed of five parts, joined together as modular parts “like interlocking legos to ease maintenance and replacement” 1) Upper body chassis: on the surface of it solar panel film would be added then sealed to be waterproof for power generation 2) lower body chassis 3)the filtration system: the filtration system would be composed of a series of membrane lining on the interior of the manta ray-shaped robot filling the hollow part of the body. The membrane would mimic the filter feeding processes of manta rays and other aquatic animals (that use the membranes in their bodies to absorb planktons). The membrane would be from the MBR kind (membrane bioreactors). There is a possibility that it could use recycled brushes (like the ones used in make-up and in painting that would still work as they begin to grow a biofilm that would act as adhesive to the microplastics). This process would mimic the industrial process in wastewater treatment plants (WWTPs). The robot submerged lower body would have a “jaw-like” mechanism that uses the wave current forces to push water from the surface area inside the body of the robot and onto the membranes. Due to the wave current motion oscillation, the lower “jaw-like” structure would keep opening and closing [getting water inside from the front as it opens then pushed it inside onto the membrane as it closes); due to how the inside of the manta ray robotic party , outside the submerging isolated air canisters (for submerging and resurfacing), is full of water at all times, once the jaw closes in due to waves pushing forces, the water would be pushed outside from water vents at the tail part (through a one-direction sieve). This would mean that the filtration process would harness the wave oscillating motion kinetic energy to push the filtered water in and out. 4) The electric components: the microcontrollers and transmitting systems, battery connected to the solar panel printed on the surface would be isolated from the water system. The sensors for aquatic phenomenon like wave motion, presence of contaminants, proximity, etc could be exposed as they are industrially manufactured and available in the market as marine tech sensors. 5) propellers and air pressure canisters: the propellers are for navigation, air pressure canisters (that could release the air in case the robot was remotely commanded to submerge below surface). The body could be made from 3D printed carbon fibers which are strong, sturdy and very light for the same hardness of much denser and heavier elements.

The water flow mechanism in the manta ray robot

Please see below the rudimentary visualization of the flow of microplastic rich water in the robot and the flow of the filtered water out (depending on the oscillation of wave motion):

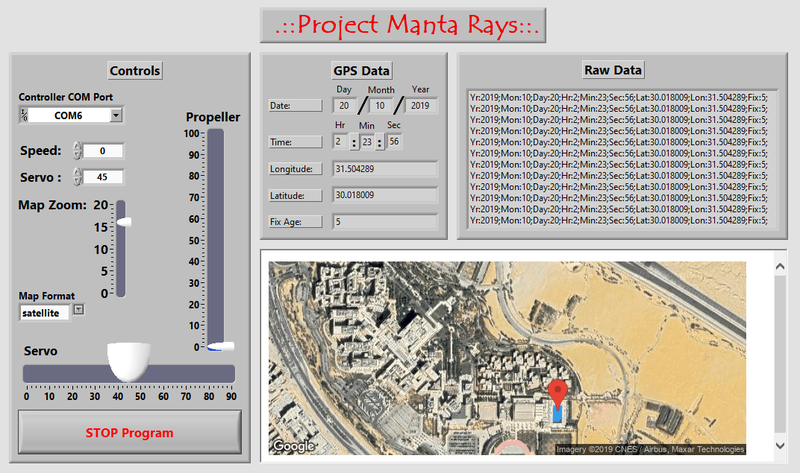

Post Script: for the sake of prototyping on the hackathon pitching day:

Scenario 1): the body would be 3D printed, fitted with the Arduino microcontroller, a sample of what the filtration membrane on the inside would look like and GPS module and propellers and their control modules would be added.

Scenario 2) there is no time to produce a physical body for the solution. The team would still program a microcontroller with the modules as if there was a physical body and the programs controlling the “hypothetical virtual robot” would be displayed as a cloud-based web application demonstrating how the robot would respond to conditions like weight sensors triggering reaching capacity of filtration and charting the navigation route back to the central station for offloading the plastics and back. The design of the robot would be shown in an interactive manner on the screen as the body would be fully designed on (Solid Works) software along with the fluid hydrodynamics as well. This scenario would include designing the robot and animating how it works using Solid Works software and fluid dynamics and hydro-dynamic forces on Ansys.

Constraints:

The design would have the following constraints / parameters:

- It has to have a minimal negative environmental impact / footprint

- It has to consume minimal energy sources

- It has to prove efficacy / efficiency in microplastics harvesting

- It need to require minimal human resources due to working in the open seas (this solution would only require human presence at the central station to perform the backwashing of microplastics membrane to offload microplastics and to operate the microplastics compressor to produce plastic pellets for transfer to mainland for recycling.

- Biomimicry: the design of those vehicles is inspired by the manta rays which are filter-feeding aquatic animals. The reason for that choice is as follows:

Solution description:

The proposed solution, “Project Manta Rays”, could be summarized as the deployment of aquatic vehicles that could be remotely controlled within a certain radius to harvest microplastics from the surface of the ocean. The design follows the following principles:

- Hydro-dynamics of the manta ray body

- The large surface area of the manta ray body allowing for its surface, exposed to sun light, to be covered with as much solar cell film to generate electricity needed to power the vehicle

- The movement through the microplastics patch, or what is called “the plastics soup” would allow water to get from the front into the filter-feeding system, go through the membranes that catch microplastics then get out of the back after being cleaned, mimicking the filter-feeding behavior of aquatic animals.

- Communication as a means to minimize the processing power at the vehicle level itself:

- Programming the communication systems, sensors and propellers on the microcontrollers (Arduino) would be tasked to [Omar Morsy & Ahmed El Zennary)

- Mechanical Design would be tasked to [Khaled Terzaki mainly and Amr Salem as support]

- Animation and graphic design: Amer Salem].

- Coordination and logistics and work on the membrane for the prototype: Abd El Hamid Sherief.

- It is energy saving: aside from relying on solar energy from the surface area exposed to sunlight; the manta ray robot would use the hydro-dynamic body to reduce the energy used in propelling the body. The design would reduce the need for propelling which would be more like giving thrusts the same way astronauts float in space mission and use the jet gases to provide thrusts for direction. Since NASA data, combined with GIS systems, would allow for pointing out the location of the garbage patches “microplastics soup”, once the manta robot reaches the assigned coordinates; the propellers would come to stationary mode and the filtration process would commence without much energy consumption.

- Bio-mimicry of the filter feeding design would allow for trapping the microplastics without using much energy, mimicking the likes of the manta rays in their feeding habits. Lots of filter feeding techniques could be applied (see picture below). Bio-mimicry designs could allow for use of recyclable materials in creation of the filter. One technique is mimicking the “Gill Raker” in aquatic animals by using recycled mascara brushes that could be used in consecutive rows to “tangle” particles.

- Manufacturing wise, the filtration mechanism would be quite easy,

- Simplicity of design: the central communication station would double as the microplastics collection center. Communication with the manta ray robots via Radio Frequency (RF) protocols would reduce the energy requirement of each robot and would reduce the processing power needed at each robot level.

- Marketability: The idea could be used for multiple business ventures:

- While the manta ray vehicle would be unmanned, it would collect information from the surrounding environment via sensors and modules: [sensor for microplastics weight in storage area, module for location (GPS), sensor for proximity, sensor for turbulence, … etc], the sensors would send the data to the microcontroller “Arduino Control Board” and then the system would send them to the central station “a repurposed anchored oil tanker that is used as marine research facility” where it is connected online and send the data to an offsite Artificial intelligence system that is meant to compare current location of the robot to the recommended locations for harvesting the microplastics “via GIS systems” then send navigation corrections to the robot via sending coordinates. The coordinates, now passed from the offsite AI system that cultivates data from GIS systems and GPS satellites, would be sent to the robot. The Arduino controller would be programmed to receive the incoming coordinates, compare them with the current local location and accordingly, give commands to the propellers (on and off) till the navigation path is set and the robot is on its way to the new destination. Since most of the navigation and journey management are done via communications from the robot (via Radio frequency transmitting and receiving modules from and to the central station and from the central station to the offsite AI system via satellite connection).

- The central station, the repurposed oil tanker, wouldn’t only have communication systems to communicate commands or get information from the robots harvesting microplastics in their vicinity, but also it would also serve as the collection station for the harvested microplastics. Once the weight sensor of the filtered out microplastics reach a certain “if” condition, It would trigger sending a message to the Arduino board which would then change its current location via charting a navigation path to the central station coordinates via propellers movement (on and off). As the robot comes back to the central station, it offloads its harvest “the filter mash bag gets transferred to the central station and the robot gets fitted with a new one”, kinda similar to changing the dust bag from the vacuum cleaner. The robot then could be sent en route with the new coordinates for the new recommended areas to clean and harvest microplastics at.

Resources and timeline:

Item | Description | Cost |

Bootcamp | Already attended by one representative in the team (Abd El Hamid Sherief) | Not Applicable |

Pre-cpmpetition | We need to 3D print a model of the manta ray robot. If there was no time to finish the design, the model would be simulated virtually on the screen | The 3D printout could be manufactured at the 3D printing lab on campus; the cost is yet to be determined. |

The competition | Two GPS modules, two Radio frequency transmission and receiving modules, weight sensor module, MBR bioreactor membrane sample for demonstration, two Arduino boards, wave motion sensor (optional), orientation sensor (optional), proximity sensor (optional), hydrocarbon sensor(optional), fluid turbulence sensor module (optional), wave speed sensor modules (optional) | To be Determined (stores were already located, El Nekheily Mall and Futures Stores). Cost is yet to be determined as some items are marked as sold out and new prices are yet to be updated. |

Human Resources | Tasks division and work plan | |

Team Members | 1: Abd El Hamid Sherief: Environmental Engineering (diploma) + ongoing graduate study in Sustainable Development (MSc, American University in Cairo). Undergraduate study in Business Finance and accounting with minor courses in Architecture. 2: Khaled Terzaki: Mechanical Engineering Graduate student at American University in Cairo (Mecatronics). 3: Omar Morsy: Electronics Engineering and nano technology researcher and graduate student (American University in Cairo). 4: Ahmed Refaat El Zenaary: Embedded systems graduate (Electronics) and currently works in the embedded systems in the automotive industry. 5: Amr Salem: Engineering graduate (mechatronics) and currently works in a Chinese company abroad with two months currently on leave in Egypt. | |

External support | Since the originator of the idea is from the three AUC students (Abd El Hamid Sherief), the idea was shared, for advice and feedback, with a professor at the Electronics Engineering Department at AUC for feedback. The professor endorsed the idea academically considering it “feasible”. The professor said that he would love to support the actual implementation later on. The same idea was presented to a professor in environmental engineering at AUC who found it interesting and worthy of experimental work. | |

Value Proposition:

The added value of the system could be summarized as follows:

- It could be used to skim oil spills: the sucked oily water could later be recycled via aeration within the body of the robot that would push the oil to float and water could be sucked from below. In that case, the robot would keep the oil and release out the water. The oil weight sensor would trigger the robot to go back to the central station for the oil to be sucked out.

- It could be used to solve the internet challenge via using the manta ray robots as stationary satellite internet signal boosters and range extenders. These robots would not be scavenging for microplastics and the extra space within the body would be used to install range extenders and signal boosting equipment that would strengthen the signal coming from the central station and work as hot spots for larger area which could benefit users on the open seas. The central station has the equipment and the antennas and satellite receiving dishes to act as satellite internet distribution hub, the network of manta ray robots, via swarming protocols, would act to increase the radius of coverage in the open ocean via acting as signal boosting towers.

- In scientific research: The manta robot could be fitted with additional sensors to investigate the aquatic environment.

- In military and warfare: The manta robots could be fitted with cameras for surface investigation; such cameras and the small size of the robot could be used in reconnaissance missions and early warning systems especially against pirates and other light targets that aren’t necessarily detected by radar and the video camera feed could give timely 24/7 feed if possible to be analyzed via the offsite AI system that is empowered by computer vision to analyze the data via the satellite link. It could also be released in swarm formations from navy ships and submarines as “sacrificial decoys” that could blow up torpedoes and marine mines from a distance away from their targets.

- In space programs: the idea could be used for the exploration of “water worlds” like Uranus and Neptune, or some moons that are theorized to hold oceans that could be liquid under layers of ice. Special “flappers” , floaters and gas canisters could be attached to extend the survivability of such probes and allow them to control which depths to descend to and send data to surface rovers until they die out , or could be retrieved if possible.

|

To Summarize: our project innovation is in usage of a communication system (Radio Frequency) to guide a semi-autonomous aquatic robot that uses biomimickry in design and filter filtration to scavenge microplastics.

Solution Charts and how it works:

Using Ocean plastic debris “garbage patches” data, the mission location would be selected.

The mission would have a central station, a repurposed oil / tanker, cruise ship, or freighter to act as both a communication/maintenance hub and also to collect the harvested microplastics harvested by the manta robots. The ship would have compression workshop to compress the microplastics into pelletsfor eventual transfer to be recycledat mainland facilities.

An example of the signal booster

range extender that could be

added to the manta ray robots to

to solve the satellite internet access issue in the ocean