Fly To Moon| Dust Yourself Off

Project Details

The Challenge | Dust Yourself Off

Fly to Moon

We aim to solve the problem of lunar dust by probing an alloy of specific substances that are able to attract particles of dust and through intensified laser, we'd be able to either melt or move the captured sample from the area of the spacecraft.

The idea is to basically collect the lunar dust speeding around the moon using rough Aluminum-Copper alloys that will attract the dust since it is electrically charged and clung to everything. Next, laser would be directed towards the Aluminum copper alloy to heat one side of it enough to change its orbit and make it escape the moon’s gravity or hit its surface. The links below provide information about the lunar dust and the laser technology.

Deliverable and Methodology:

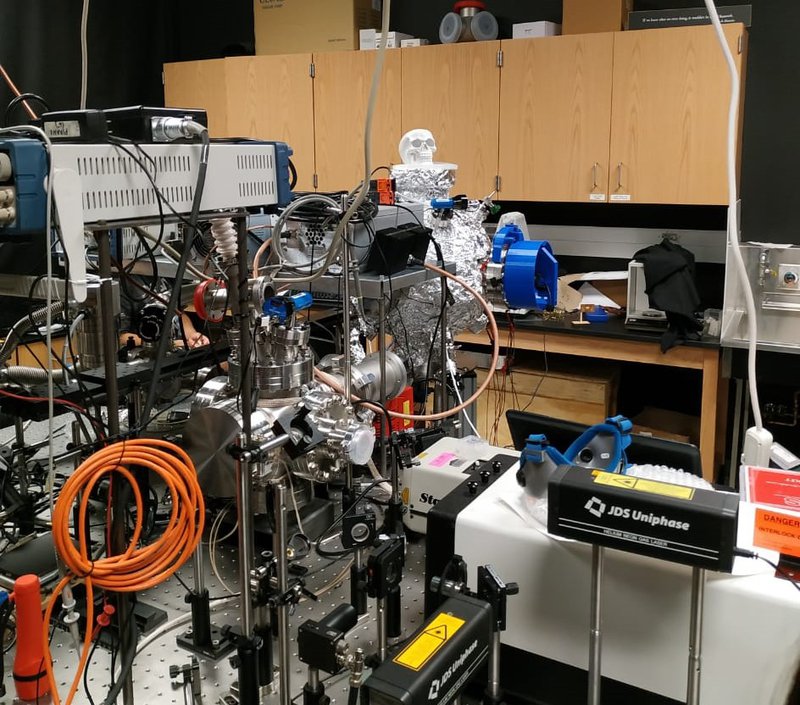

The purpose of the experiment was to expose energy to different samples of aluminum with different

roughness in order to determine how much energy each sample reflects. Accordingly, specific

procedures were followed. Firstly, different samples were prepared using silicon carbon abrasive discs

(36 – 1200 grit) placed on a lapper (TED PELLA, XP 8 grinder/polisher).

Secondly, using 3D optical profilometer (Filmetrics, 3D profilm), the samples were scanned to quantify

the surface roughness.

Thirdly, a thermistor (Apogee ST-200) was placed underneath the sample in an insulation block. Then,

the laser was fired (Continuum, YG-660), and the energy of the beam was measured with pyroelectric

energy sensor (Gentec-e QE series). Afterward, the data was collected from the thermistor, which was

attached to Omega data logger (OMEGA Om-usb-temp). Finally, the amount of absorbed energy by the

sample was calculated. By calculating the difference between the fired energy and the absorbed energy,

the reflectance of each sample was calculated.

Resources:

https://www.researchgate.net/publication/245307656_Lunar_Dust_Levitation

https://www.sciencedirect.com/science/article/pii/S0921883114001927

Presentation: