Moon Riders| Eeny, Meeny, Miney, Sample!

Team Updates

Background

Sample acquisition has been done up to now at a very low level. The main limitations were due to the fact that human exploration is very dangerous and is constrained by the life support technology (TRL and size). Also because humans are not designed to survive in space and extraterrestrial planets, a space suits are required to be worn by the explorers, thus greatly reducing mobility, dexterity and vision. Considering all this and in the perspective that human life is the most important resource in space exploration, engineers should develop new solutions to minimize the human risks and delegate as many tasks as possible to robotic systems.

As seen in previous mission, robotically space exploration has been done only on reduced areas without the potential to analyze an entire specific area. This is mainly due to the reduced mobility of any rover imposed by the engineering limitation set by the requirement of low power consumption.

Description

Looking at the space robotic State of the Art, an innovative solution was required to be implemented in order to remove the restrictions of low mobility and restricted exploring area that exists nowadays. Considering also the need of reducing the EVA time that astronauts are required to spend in doing science/sample acquisition, the Moon Riders team has initiated the development of a primary project design to achieve all this.

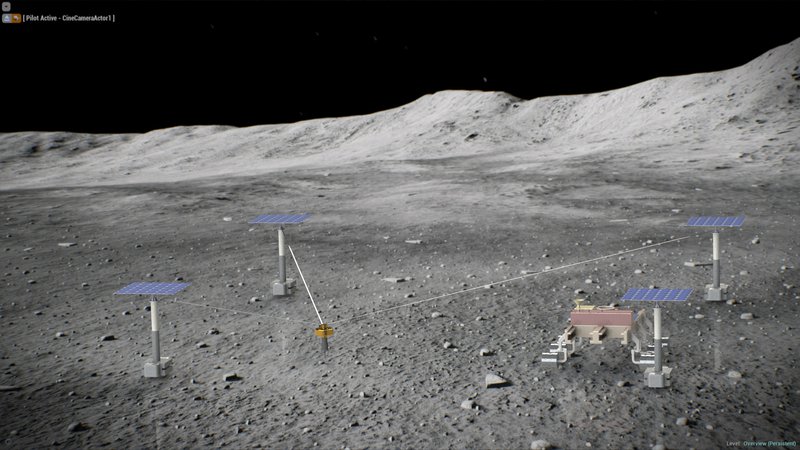

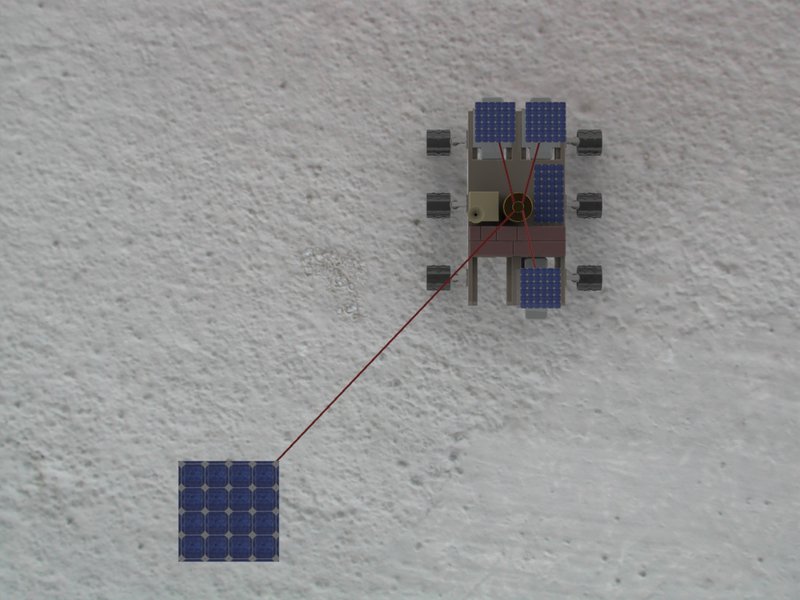

We are proposing an innovative solution, Moon LAB, which is based on a robotic system in charge with deploying itself, scanning and retrieving scientifically valuable samples. The system is made of two main sub-systems, one for mobility and deployment of the other, and the second one for sample searching and retrieval.

The innovation of this project lays in the type of mobility of the scientific payload that we are proposing. In our vision, a small cylindrical effector is connected with four different wires to four different structural poles. The wires suspend above the ground the scientific payload though means of tension. Controlling the length of the wire, the scientific payload can be moved around the inner area between the four poles, but also its elevation. As means of technology, the scientific payload has the ability of interchanging its scientific instruments by an end effector connection. This connection is considered both as electrical and data interface and is taken as baseline Dust-Tolerant Connector Operation developed by NASA’s Kennedy Space Center. Other dust-removal/protection systems developed by NASA were considered in the development of the project. One of many scientific heads that the payload could operate are, but not limited to, a small drill (such as SD2 from ESA’s Rosetta Mission) for retrieving small samples from under the lunar surface, a scoop (such as Nasa’s Mission Phoenix) for gathering dust or pebbles, scientific scanners such as Ground Penetrating Radar, X-Ray analyzer, Microscopes and many more.

The mobility system will consist of a rover similar in size and design with NASA’s Mars 2020 rover which will be responsible with placing the four-structure poles at the designated location to be able to do science. The rover will be responsible of carrying the interchangeable heads for the payloads but also the scientific box where the samples will be stored and/or analyzed. The control of the rover would be mainly autonomous with no need of human interaction, except in non-nominal situations. The human operator/astronaut could take full control or monitor the health diagnostic of the rover, through the dedicated application.

Potentially using Nasa’s topographical map of the moon, a preliminary inspection location can be selected my means of data processing algorithm (under development). The algorithm would take the topography data and determine the slopes of the terrain in order to identify a feasible route for the rover to reach the inspection area. Also a mapping of the non-accessible areas can be determined in order to plan and detect an area of interest for scientifically purposes. Lunar topography can be collected by the results of LOLA (Lunar Orbiter Laser Altimeter)

Computer Vision technologies can be used and integrated in the system in order for the rover to be able to autonomously detect and reroute itself when in front of an obstacle.

Challenges faced

As observed since the first man walked on the moon, lunar dust is a major challenge for all systems and sub-systems, especially for moving parts. Fortunately for us, due to extensive work done at NASA this challenge has been minimized through under development cutting-edge technologies. Even though the aim of the project wasn’t to find a solution for lunar dust mitigation, the negative effects were considered as a driver in the design.

The deployment of the poles was a critical point due to their impractical size which would be challenging for storing them properly. In this design we opted for a long telescopic actuator which could be improved in the future iterations.

As seen in Europe Space Exploration Missions, anchoring is a critical point and hard to design, especially when the terrain could be composed either by stones, pebbles or dust. We chose to use a screw anchoring device mainly because they give a higher anchoring reaction force. This design could be further improved considering concepts such as other gripping mechanisms.

Future Developments

Besides the virtual infinite number of end effectors that could be installed on a scientific payload, having a moving platform above the surface opens new opportunities for future missions. Having in mind the 3D Cartesian Coordinate Printer, Moon LAB could be used as a mean to build large scale 3D printed infrastructure. This horizon is in line with Nasa’s future missions planning for Moon returning where Moon LAB could give the infrastructure for rapid habitat building.

Moon LAB is an innovative autonomous system for searching and gathering scientifically relevant samples from lunar surface

Technologies used:

- Solid works for modelling the component’s and system’s overview.

- Gimp for photo and editing and rendering.

- Microsoft Power Point for the presentation.

- A preliminary mock-up of the software coordinating the system has been thought of and implemented using basic UI technologies (HTML, JavaScript and CSS).

Resources

https://mars.nasa.gov/mars2020/

https://www.nasa.gov/mission_pages/phoenix/images/press/isad2.html