MechBit| The Memory-Maker

Project Details

The Challenge | The Memory-Maker

MechBit

A comprehensive micromechanical digital solution for mechanical memory based on curved surface actuation by impact force. Writing, reading and erasing data in full or parts of it is possible, using actuating force and external pressure.

Introduction

Memory that relies on electromagnetical phenomena has manyadvantages and has helped to initiate the computer revolution but on extremeenvironments and adverse conditions it can be unreliable and problematic ineach use. A notable example of such conditions can be observed in the case ofVenus where the extremely high temperatures make it impossible for traditionalelectronics with semiconductors to survive for more than few hours. For theabove reason, any attempt to explore comprehensively this and similarenvironments requires mechanical based systems where even the processing powerand memory use basic mechanical principles. Our team was assigned the challengeof designing a system that can store ideally 1MB of digital data in arelatively small space. Dependant on the above and various more constraints we havedeveloped a completely novel solution capable of storing binary data withminimal or no reliance on electricity.

Though Process and Conceptualization

In order develop that solution wehad explored various other means of mechanically storing information such asfluid-based flip-flop registers and bent wire representing the two digitsdepending on the bent direction and being fed through and to a spool. Furthermore,it was also suggested representing more bits with the use of hex or other countingsystem. One likely idea was a loom-like device which stores binary informationin the form of a "fabric" pattern creating a pattern of over and underthreads representing 1s and 0s and having immense memory capacity.

During our thought process and brainstorming session, we setspecific goals and specifications which our system should accomplish. Some ofthem were the idea of utilizing the extremely high-pressure difference that oursystem – and accordingly AREE – will encounter in Venus, and the extremely hightemperature present as a way to more easily handle and morph metalliccomponents, making them more pliable.

In the end, based on hard drivesand first concepts of pick-ups, the idea that prevailed was cylinders or drum containingbits to store the data as will be explained further down.

Final Concept

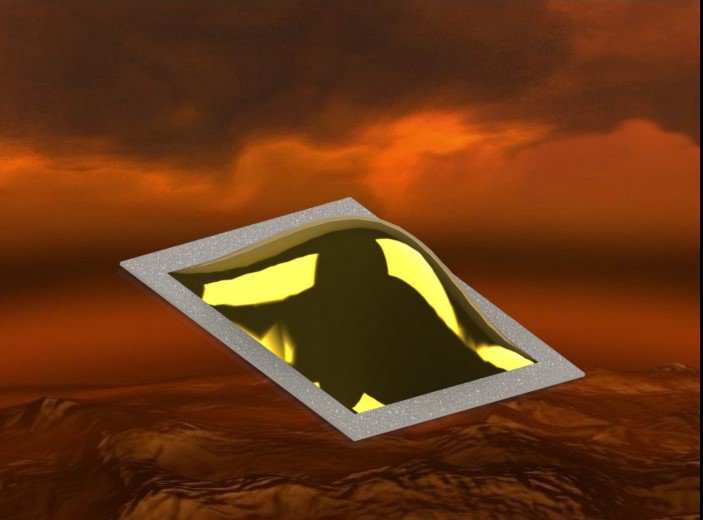

The main point of storing memorywith a mechanism in our case is based on a bent surface with two stable pointsof equilibrium and one unstable. Each bent surface has one unstable point whereit is flat and even a small instability will cause it to change to a stablepoint and two stable points of equilibrium when it is bent towards the positiveand the negative axis. In our mechanism, called MechBit, and seen in the imagebelow, the zero state is on the negative axis and the activated or single stateis on the positive state. Each MechBit represents, of course, one bit of digitaldata and multiple MechBits can be stored in a series to increase the memorycapacity. The MechBit should be constructed using a light and reliable metalsuch as titanium and can be expected to have a read-write capability of tens ofthousands of times.

Of course, static and dynamicanalysis will be needed to assert that such a mechanism can withstand theadverse conditions as well as the constant writing and erasing of data that mayoccur during a month or year-long mission on Venus. Such analysis may require explicitdynamics with impact, frequency response for vibrations caused by the movementof the rover in uneven soil and fatigue analysis for the continuous writing anderasing.

In our case, 1MB of data is storedin 11 drums each with approximately 100KB of data. As can be seen in the imagesand drawings below, the MechBits are stored on the drums in a helix vertical tothe main axis and are actuated upon and read with a head mechanism movinginside a thread on the drum. The needle that writes and reads is moving on athread for the same reason that the MechBits are vertically to the main axis.This is done in order to prevent vibrations from the movement of the vehicle tomove the needle and change various memory cells.

The data is written using a needle,as stated before, which either forces the MechBit to the single state or leavesthe MechBit in the zero state. The actuating force will be analog and between 0and 1 as stated in the conditions of the challenge but will be converted usinga spring to digital data. Indeed, the spring will act as an Analog to DigitalConverter (ADC) with a cut-off for the zero state on the 0.5N mark and below.After accessing the MechBit to write data, using a trapezoidal nut and screw,the linear actuation of the signal force is converted to circular motion and islater transferred to the drum with a driving belt forcing it to turn by a predeterminedangle to access the next MechBit. This is done to prevent the use ofcontrollers and micro-electronical systems. When the needle reaches the end ofthe drum a mechanical switch is activated in order for the needle of the nextdrum to begin writing on its memory. Of course, with more information about therover and its actuators and sensors the various drums could act as different “disks”of the system. This would mean that various sensors could write to different drumpreventing the loss of data and achieving parallel writing capabilities.

In order to read the data, thesame mechanism is used in which case the needle will be move negatively if thedata is in the zero state and positively if it’s in the on state. In order forthe needle to move a mechanical switch would be activated and either anelectrical motor would start or power from a wind turbine would be diverted tothe drum and the data would be read. The spring that was used as an ADC in the writingscenario, could be used a DAC and the data could be transmitted accordingly.

Last but not least, the act oferasing the data to be re-written could be achieved with a mechanical valve onthe side of the drum which would increase the pressure inside the drum by apredetermined amount each time. This would force all the MechBits to invert tothe zero state and new data would be written. This pressure would be availablefrom the external environment in which case the drum should be insulated fromthe rest of the system and that from the environment This is needed for apressure difference to occur between the two. Indeed, for this to be properly beimplemented extensive analysis would be required both for the operationalaspect as well as for the material one. It should be noted that this system haslimited times that can be used as the pressure inside the drum would, at somepoint, surpass the available signal/actuating force of each MechBit.

Impact

It is obvious that such system,based on traditional designs and parts, with innovative use of mechanics andspace can achieve great efficiency of storage and reliability in adverseenvironment. With proper development and implementation this design couldachieve a mechanical revolution in the computing and technology space.