SpaceBakers| The Memory-Maker

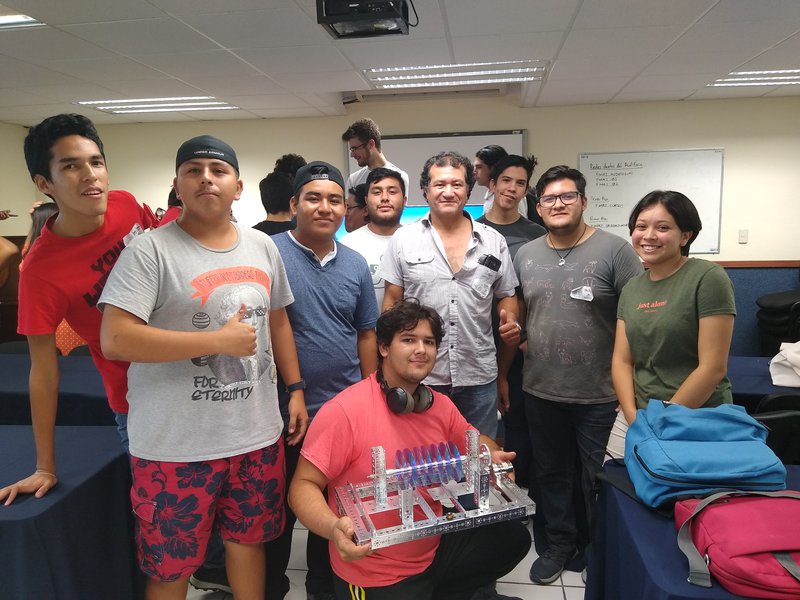

Team Updates

Notes:

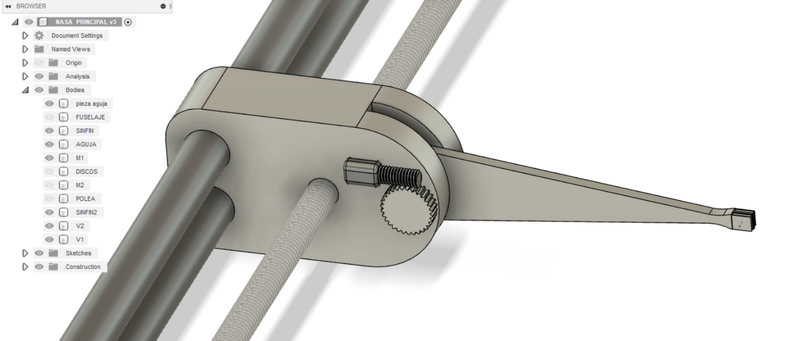

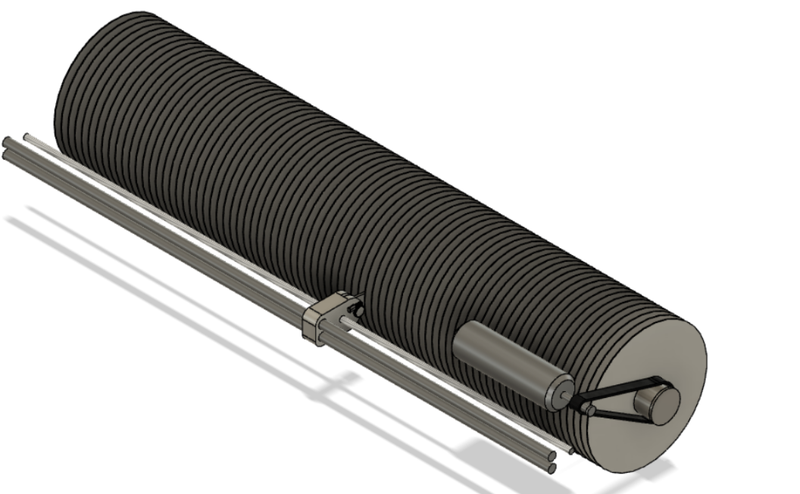

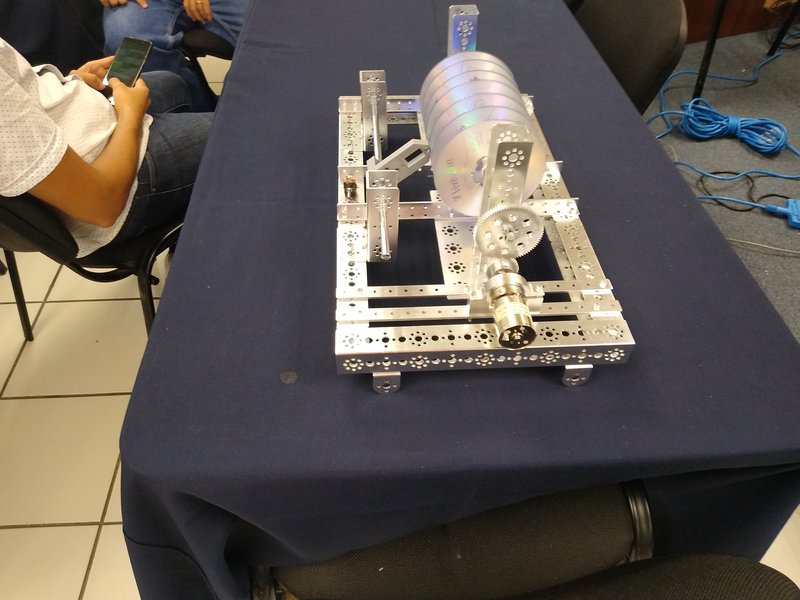

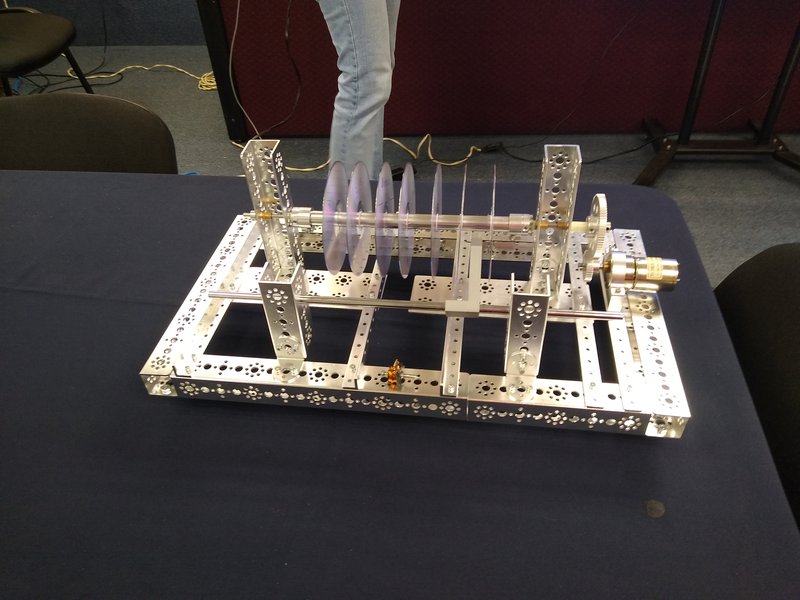

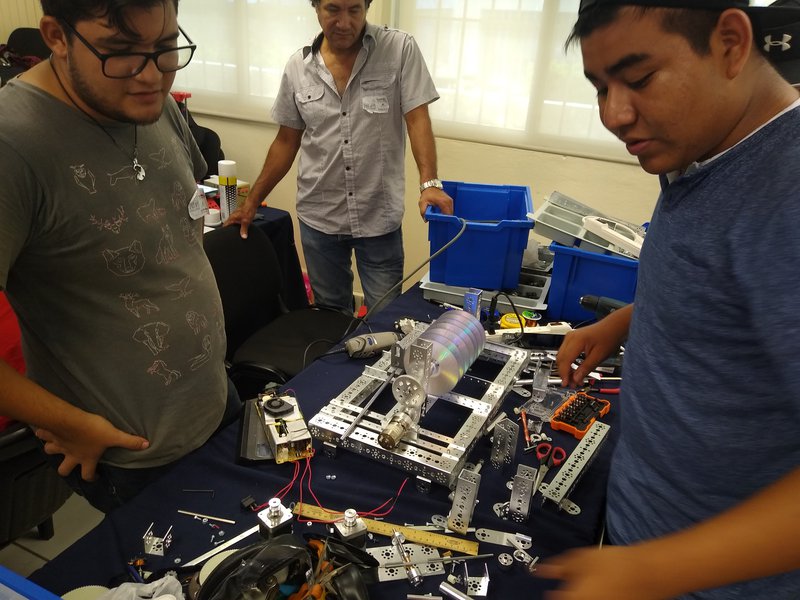

1.-To rotate the disc assembly, a small motor with a reduction box is used in conjunction with a gear transmission (different from the 3d model)

2.- all engines have reduction

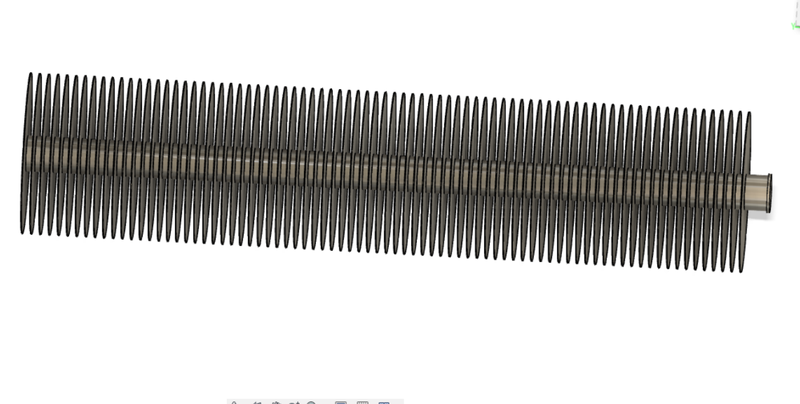

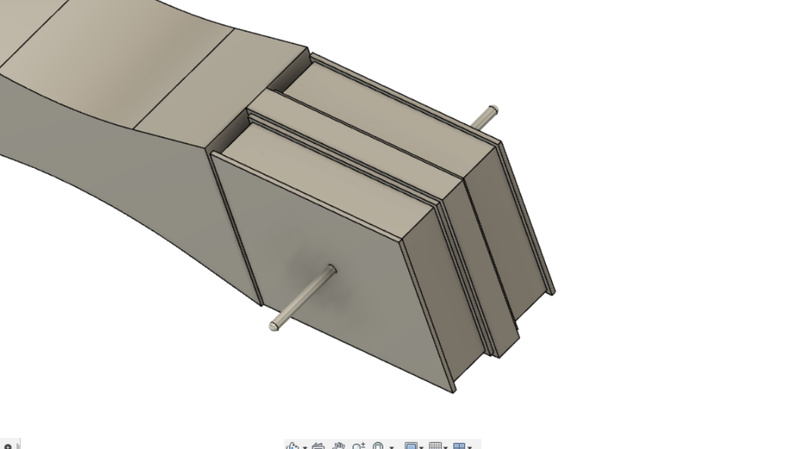

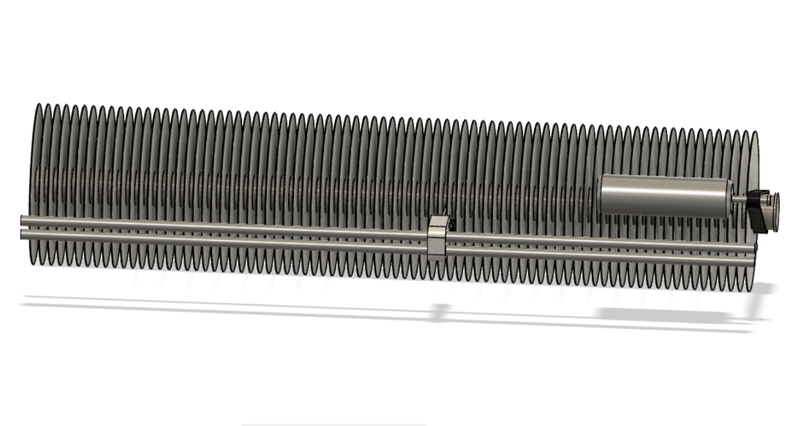

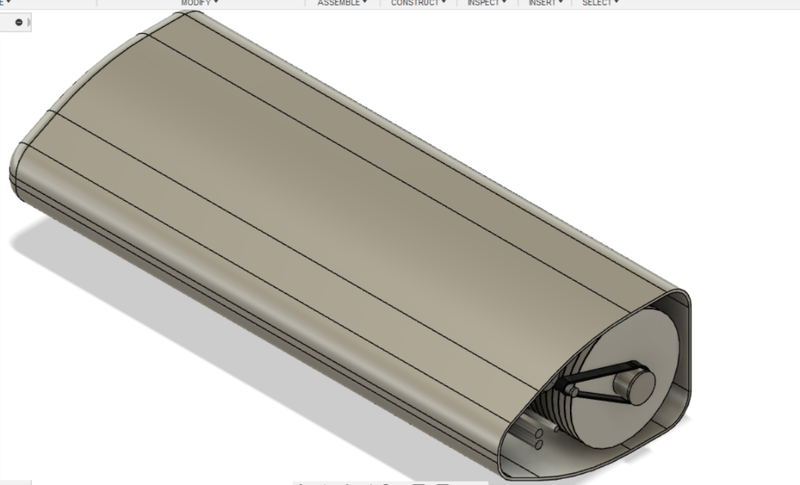

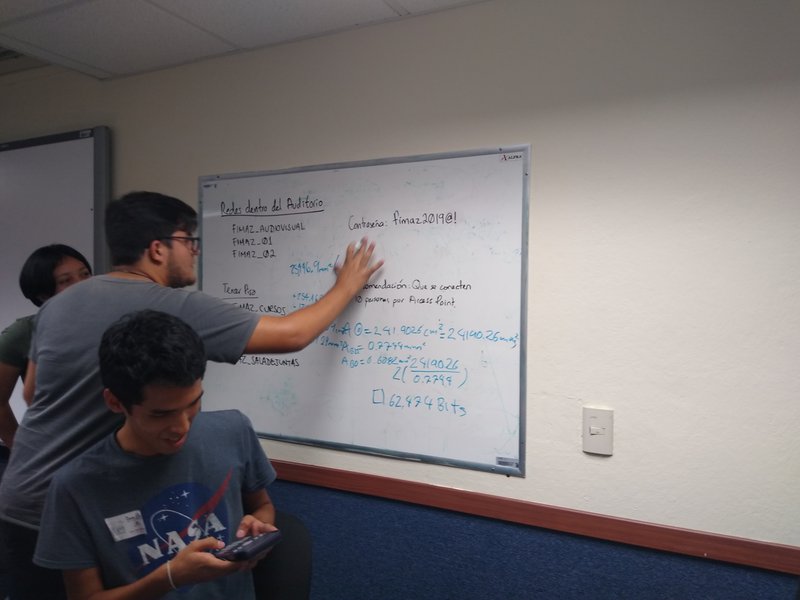

Our project is a mechanic storage system consisting of 80 titanium discs (to obtain 63.2 MB) covered with a fine thin cape of graphite (1 µm), for the system of graven of data we have based in the system that the Hard-Disk-Drives use, since we use a needle that moves around the disc and with a tip of tungsten carbide placed in an electro magnet we made the tip hit to the disc, removing the cape of graphite letting a point by way of a bit. The use of titanium and graphite on the discs of graven is because the titanium is highly reflective and the graphite is dark, what makes a contrast doing easier the lecture of the bits by optics mediums.

The way that we control the system of graven is with relays (in a configuration of logical gates). This relays will be the receiver of all the external information and being in charge of the transformation that digital information in mechanic information. The set of relays will have a system of control which will be a pre-graven plate who commands how and when work, will be in charge of all the protocols of function from the beginning, the process and the end of all the capture of information.

Our project have around of 22Kg of mass in a dimension of 20cm*32cm*83cm, being able to storage 63.2MB of memory (0.79MB per disc) accomplishing the requirements.

3D model: https://a360.co/31RxqVk