Project Details

Awards & Nominations

SSI3 has received the following awards and nominations. Way to go!

The Challenge | The Memory-Maker

Echoes from the Past: Mechanically Integrated Memory System(MIMS)

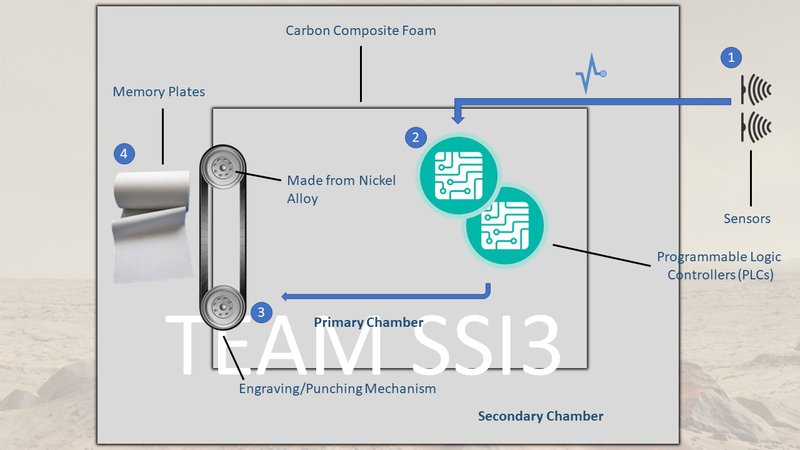

SSI3 aims to solve long term memory storage issues in planetary rovers on hostile planets. Our idea involves mechanical memory etching and punching. With powerful PLCs controlling the output of punching machine, it will solve the issue once and for all!

Background:

Venus being a hostile planet, with extreme temperatures (450-60 degrees Celsius on average) is a nightmare when considering long term data storage on rovers. Traditional electronics do not work. There is no chance of information returning to Earth without being altered.

Our Idea:

What we propose is a Mechanically Integrated Memory System (MIMS) to do the job. A mechanical punching machine coupled with powerful PLCs can be made capable of punching planetary data both in Binary and Morse Coding.

Working:

MIMS is proposed to have following components:

- Sensors: cameras, thermal sensors, Nephelometers etc will provide analog signals to the the specially designed PLCs.

- Programmable Logic Controllers (PLCs): These will not be ordinary PLCs. Created from Silicon Carbide ( or any other heat resilient material, we don't really know any material specifically), these special PLCs will process the analog data and convert it to binary and morse coding. PLCs will also control the mechanical Punching Machine and output Binary and Morse Data using it.

- Mechanical Punching Machine: A mechanical punching machine to take input from PLCs and punch it in the form of binary and morse coding. Just like back in the old days when typewriters and ticker tapes were used for punching data on paper. Works on the principle of conveyor belt. The pulleys on which conveyor belt will move are made from specific nickel alloys e.g. Inconel (Ni-Cr alloy). This will minimize the internal heat generated via this mechanical process as Inconel is extremely heat resilient nickel alloy.The punching component is a needle like part pivoted at a point, capable of moving along two axis.

- Memory Plates: The most important component. These special plates will be capable of keeping data unaltered over a long time under extreme environments. One good material that can be used for this purpose is Ceramic Fiber Paper. This paper is light weight, flexible and has good handling strength and can withstand temperatures varying up to 1093 degrees Celsius. Once the data is punched, these memory plates can be collected from a depot on the planet and brought back to Earth.

- Datasets: Mainly, we can split our data into two types: Image data and alpha numeric data. As in Satellite Remote Sensing, raster images are in the form binary values for each pixel of an image. Therefore each memory plate can be coded separately for image datasets which can be rescanned into images. Another idea is to use BUFR (BinaryUniversal form for the representation of meteorological data) and GRIB (Gridded Binary datafor meteorology) dataformats which are used by meteorologists to create images for atmospheric phenomena. A good reason to use these datasets is because they also store metadata along with image data in binary format which in our case is extremely necessary.

However, a modified morse code specifically designed to code planetary data can also be used such that it uses the same amount of space on an A4 memory plate ( which can store almost 0.7MB of alphanumeric data).

To maintain the working environment for our setup, our setup will use two chambers. One with PLCs and Mechanical Puncture and the second one enclosing the first and containing Ceramic Fiber Paper sheets rolling over in front of punching needle. The shielding mechanism can be an aerogel (source: NASA opensource) which was specifically designed by NASA to cater shielding needs on Venus rovers and Orbiters. Or we can use Carbon foam encapsulated between carbon plates like on Parker Solar Probe.

Furthermore, to maintain our setup at feasible temperature, water can used just as in the radiator of a car. Since the sink temperature is much higher as compared to what source temperature can be therefore passive cooling systems will not work. Water on the other hand can be circulated around the setup in pipes which in turn will keep it cool.

In a nut shell, we believe in learning from our past. When we did not have any powerful electronics to logically run our peripherals, we had a tough time with driving our inventions. Now that we have PLCs which are already being used in industrial applications, we can make a much more powerful mechanical system that can serve our needs.