Hyperion| Fly-by-Wireless

Project Details

The Challenge | Fly-by-Wireless

Union Sense

The reduction of the weight of an aircraft is something crucial, since the reduction of weight implies a reduction in the fuel spent on flights, for this the system of electrical and electronic connections will be redesigned.

Background

A large commercial passenger aircraft has more than 100,000 wires, with a total length of 470 km and weight of 5,700 kg. There is about 30% of additional weight in harnessing and connectors. About 30% of electrical wires are potential candidates for a wireless substitute. Wiring lacks dissimilar redundancy and has limited maintenance flexibility and access. Many bulkhead penetrations and connectors are needed between compartments, into tankage and to pass from interior to exterior. Many permanent and temporary sensors are not added because of wiring efforts and associated weight.

The Modular Instrumentation System project is developed to support functions required for space environments, the MIS Project is focused on flexibility, reusability and economical ways to develop electronics and instrumentations for space applications. The project application is focused on the instrument and sensor technologies to support remote sensing, and for in-space and planetary surface activities, especially in life support and habitat systems and in-space vehicle systems supporting data acquisitions and sensor interfaces.

Objective

The main objective of Fly-by-Wireless is the reduction of wiring in aircraft, for a decrease in weight and fuel consumption. The electrical and electronic systems of commercial and private airplanes and rockets are very similar, so the reduction of wiring in these systems would imply the possibility of a redesign in the various aircraft mentioned previously.

Our proposal

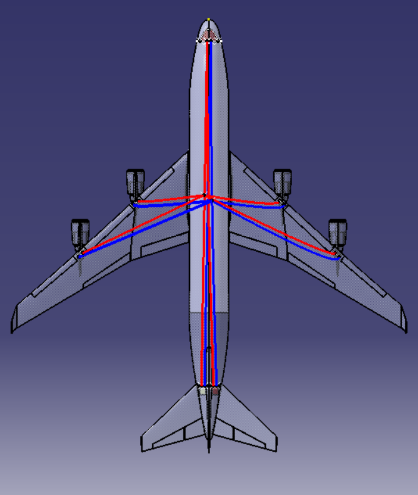

Although the challenge is to look for a wireless solution, our proposal is to use a single connection for the transmission of an internet and electric power network, in this way we can distribute this energy and interconnect the different telemetry and control systems, through Power Line Comunication and the possibility of using radio frequency identification to measure the data of various passive sensors without the need for physical connections.

What do we need?

The design is based on the implementation of a single system of alternating current power lines made of aluminum with a thickness of 5mm and a width of 25mm, which is isolated and distributed to the plane completely. The power line is interconnected in a modular way to the various avionics modules using Power-Line Communication and RFID technology.

How does it work?

The implementation of PLC (Power Lines Communication), allows data to be transmitted through alternating current lines. This works by modulating a carrier wave whose frequency ranges between 20 and 200 kHz which is incorporated into the electrical power wiring from the motor power generators.

PLC devices are used as substitutes for Ethernet networks, specifically one, the use of several PLC devices is equivalent to an Ethernet connection with shared access means, that is, it is as if we were connecting the computers to a hub instead of a switch, so communications are half-duplex.

The way of transmitting the data is similar to the operation of the ADSL lines (which separates the voice from the data). First, the frequencies are filtered, so that the digital information and the noise of the electrical signal can be separated from the data.

Thus, PLC technology opens a wide range of possibilities in the communication of technological devices.

Tools used

- Catia V5

- HTML

- MySQL

References

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa....

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa....

- https://pixabay.com/es/vectors/mundo-la-tierra-map...

- https://grabcad.com/library/laser-cut-model-plane-...

- https://es.vexels.com/png-svg/vista-previa/136278/...

- https://grabcad.com/library/boeing-747-1