Universal-ARGE| Warming Planet, Cool Ideas

Project Details

The Challenge | Warming Planet, Cool Ideas

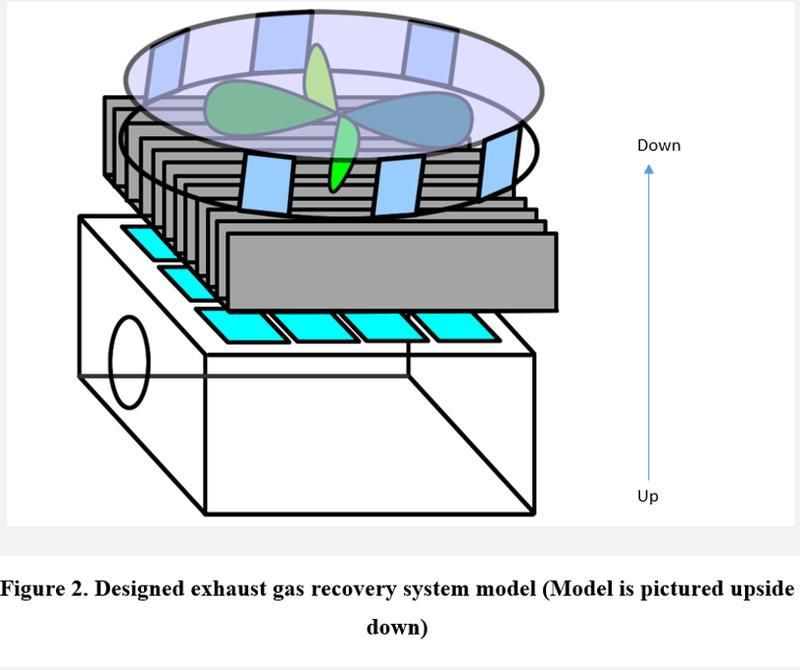

Alternative Thermoelectric Generator Systems

We are planning to use these Thermo Electric Generators to decrease the overall exhaust gas production and help the enviroment to be a cleaner place. At the same time we are increasing the battery life of the cars.

We expect a significant increase in energy savings in the long term with the TEG technology used. This energy saving has varied as the temperature difference in the assembly, or the type of conductor, has changed. For example, when the cold face is 6.5 C° with ceramic TEG module, the hot face is 46.5 C°, 1 module with 1.5 volts, 2 modules with 2.5 volts, 4 modules with 4.5 volts, 8 modules with 8.5 volts energy is obtained. This system will be connected to the vehicles, so much more thermal difference will be generated and the energy outcome is much more than expected. In addition to the energy gain, exhaust gas, which is seen as waste in vehicles, was also used. Thanks to the energy provided, the energy used by the vehicle is met and the pressure on the battery is reduced. Therefore, the battery life has been extended. Thanks to the extended battery life, the expenditure on the battery has decreased and economic gains have been achieved. By using the thermal energy of the exhaust gas released into the air, the damage caused by the exhaust gas to nature has been reduced as much as possible.As resources we used some books and we asked our physics theachers to make sure it doesn't fail Here are the resources that we used;

[1] J.G. Haidarand J.I. Ghojel. Waste heat recovery from the exhaust of low-powerDiesel engine using fabrication and evaluation of SiGe/electrode. Proc. 16th International Conference on Thermoelectrics. 1997. Dresden, Germany. p. 599-602.

[2] Birkholz, U.,Grob, E., Stohrer, U., Voss, K., Conversion of waste exhaust heat in automobiles using FeSi2 thermo elements, Proceedings of the 7th International Conference on Thermoelectric Energy Conversion, Arlington, USA; 1988. p. 124-128.

[3] Bass, J.C.,Campana, R.J., Elsner, N.B., Thermoelectric generator for diesel engines,Proceedings of the 1990 Coatings for Advanced Heat Engines Workshop, USA.;1990.

[4] Kobayashi, M.,Ikoma, k., Furuya, K., Shinohara, K., Takao, H., Miyoshi, M., Imanishi, Y.,Watabane, T., Thermoelectric generation and related properties of conventional type module based on Si-Ge alloys, Proceedings of the 15th International Conference on Thermoelectrics;1998.

[5] Thacher, E.,Helenbrook, B., Karri, M., Richter, C., Testing of an automobile exhaust thermoelectric generator in a light truck, Proceedings Ins. Mech. Eng. Part D, Automobileeng.,2007. 221 (1): p.95-107.