Project Details

The Challenge | The Memory-Maker

Memory Roll

Memory Roll aims to store memory mechanically in the form of binary digits under the severe conditions of atmosphere faced on Venus.

Considering the issues pertaining to the use of electronics in the ambiance of Venus, we decided to make a fully mechanical system with materials resistant to the environmental conditions there.

Our system comprises of a gear system which actuates an indenting arm to punch and mark data on a thin sheet of Gold. Gold was chosen considering its low hardness making it easier to indent, lack of reactivity with most chemicals and its high melting point. The gold sheet will be wounded around the rolls with the sheet being 0.02 cm thick. The length of the sheet that could be rolled is enough for storing around 2 MB of data within the given spacial concerns.

The gear system would be manufactured of Rhodium since it is a non-reactive and hard metal. As the actuation of the arm over the sheet is in millimeters or even less, we will be utilizing the power of high gear ratios which can be achieved by the usage of worm gears. Accurate design and calculations of the gears will result in a well calibrated system which will be able to utilize the area of gold sheet efficiently. Increased accuracy can exponentially increase the amount of data which can be stored. Our calculations were based on one bit per centimeter but this can be significantly improved to 1 bit per nanometer depending on the accuracy and manufacturing of the system.

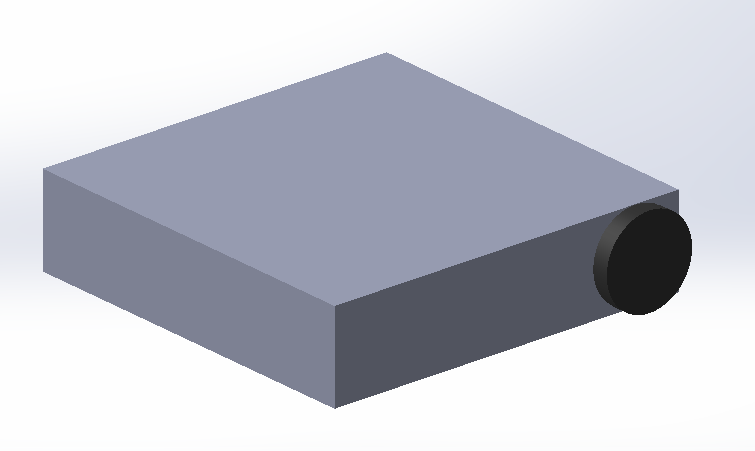

For data entry, torque will be applied on the main gear which is shown in the project picture in black color outside the box. The system works on 2 values of torque which depends on the binary digit. If binary digit ‘0’ is received, a torque of 0.01 Nm will cause a 5° rotation of the indenting arm. It will, however, not be sufficient to cause a piercing by the needle on the metallic sheet. If binary digit of ‘1’ is received, a torque of 0.05 Nm will be delivered causing a 5° rotation as well as a further 5° rotation caused by the piercing of the metallic sheet by the needle on the indenting arm. Whichever the case, the arm will move forward by a centimeter after every binary data entry on to the sheet. At the end of the sheet, the gear system will move the arm one cm downwards for another line of storage.This will continue to store data until the sheet reaches its final line of data entry.

Data can be read simply by linear movement of a rod, lesser than the size of the piercings, over the gold sheet. The movement is to be done in the same pattern as it was stored.

For formatting the memory, a mechanism can be designed which will hot-press the sheet. The plate used for pressing the sheet can be heated electrically.

A complete working CAD assembly can be made with proper gear system calculations. Such an assembly can animate the entire system explaining it with more clarity. Given the time constraint, we were unable to finish our CAD assembly.